1. Electric Powder Coat Oven Components and Design

An Electric Powder Coat Oven uses electric heating elements (coils or infrared panels) to cure powder coatings at 300°F–450°F. Key components include an insulated steel chamber, temperature controllers (IoT-enabled in 2025 models), airflow systems, and heat-resistant racks. Modern designs integrate recycled insulation materials and modular setups for easy upgrades like UV-curing add-ons.

2. Applications of Electric Powder Coat Ovens

These Electric Powder Coat Ovens are used in automotive (bike frames, engine parts), industrial machinery (pipes, valves), and DIY projects (furniture, tools). Solar-ready 2025 models also support eco-conscious manufacturers curing coatings on solar panel frames or EV components.

3. Electric Powder Coat Oven Price Ranges 2025

- Small benchtop units

: 1,500–4,000 for hobbyists.

- Mid-sized industrial ovens

: 8,000–25,000 with conveyor belts.

- High-efficiency solar-electric hybrids

: 12,000–30,000, reducing energy costs by 35% over 5 years.

4. How to Use an Electric Powder Coat Oven Correctly

Preheat to the powder’s specified temperature (check manufacturer guidelines).

Arrange parts evenly on racks to ensure uniform heat distribution.

Set timers (10–30 minutes) based on material thickness.

Use cooling zones or gradual temperature drops to prevent coating cracks.

Clean the chamber after each cycle to avoid residue buildup.

5. Choosing the Best Electric Powder Coat Oven

- Size

: Select a chamber 20% larger than your largest part.

- Heating type

: Infrared for speed, convection for complex geometries.

- Certifications

: Prioritize UL 508A or CE-marked models.

- Future-proofing

: Opt for 2025-ready ovens with IoT connectivity and solar compatibility.

6. Safety for Electric Powder Coat Ovens

Install fire-resistant insulation (ceramic fiber or mineral wool).

Ground all electrical components to prevent shocks.

Avoid overloading circuits; use dedicated 240V outlets for high-power models.

Regularly inspect heating elements and replace worn parts.

7. Efficiency of 2025 Electric Powder Coat Ovens

Modern ovens prioritize sustainability:

- Energy recovery

: 25% of heat is reused via recirculation systems.

- AI optimization

: Adjusts curing cycles in real-time to cut energy waste.

- Modularity

: Swap components (e.g., coils, sensors) without replacing the entire unit.

Q: What maintenance ensures electric oven longevity?

A: Clean vents monthly, test thermostats quarterly, and replace coils every 2–3 years.

Q: Are UL-certified electric ovens safer?

A: Yes—UL 508A certification guarantees compliance with electrical safety standards.

Q: Can electric ovens cure thick metal parts?

A: Yes, if designed with 450°F+ capacity and reinforced insulation.

Q: Do solar-ready models work off-grid?

A: 2025 hybrids can operate on solar power but require battery backups for consistency.

Q: How do IoT features improve curing?

A: Remote monitoring and automated profiles reduce errors by 40%.

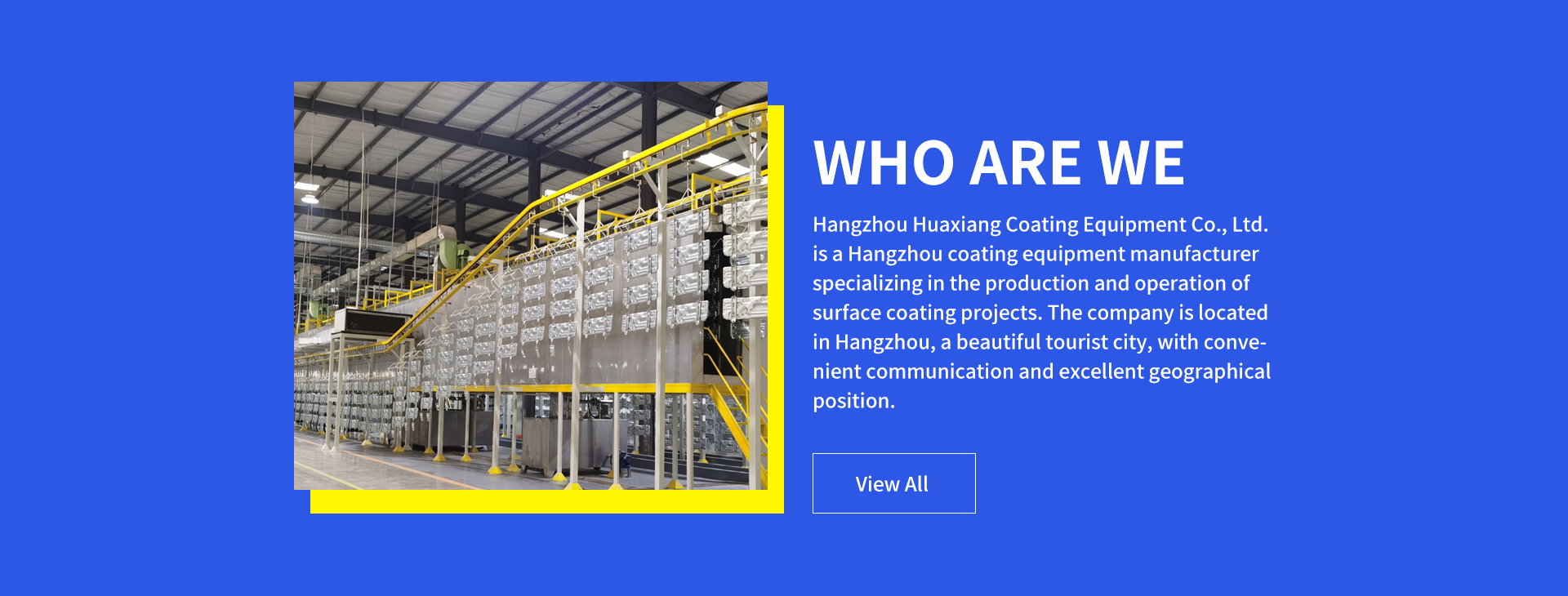

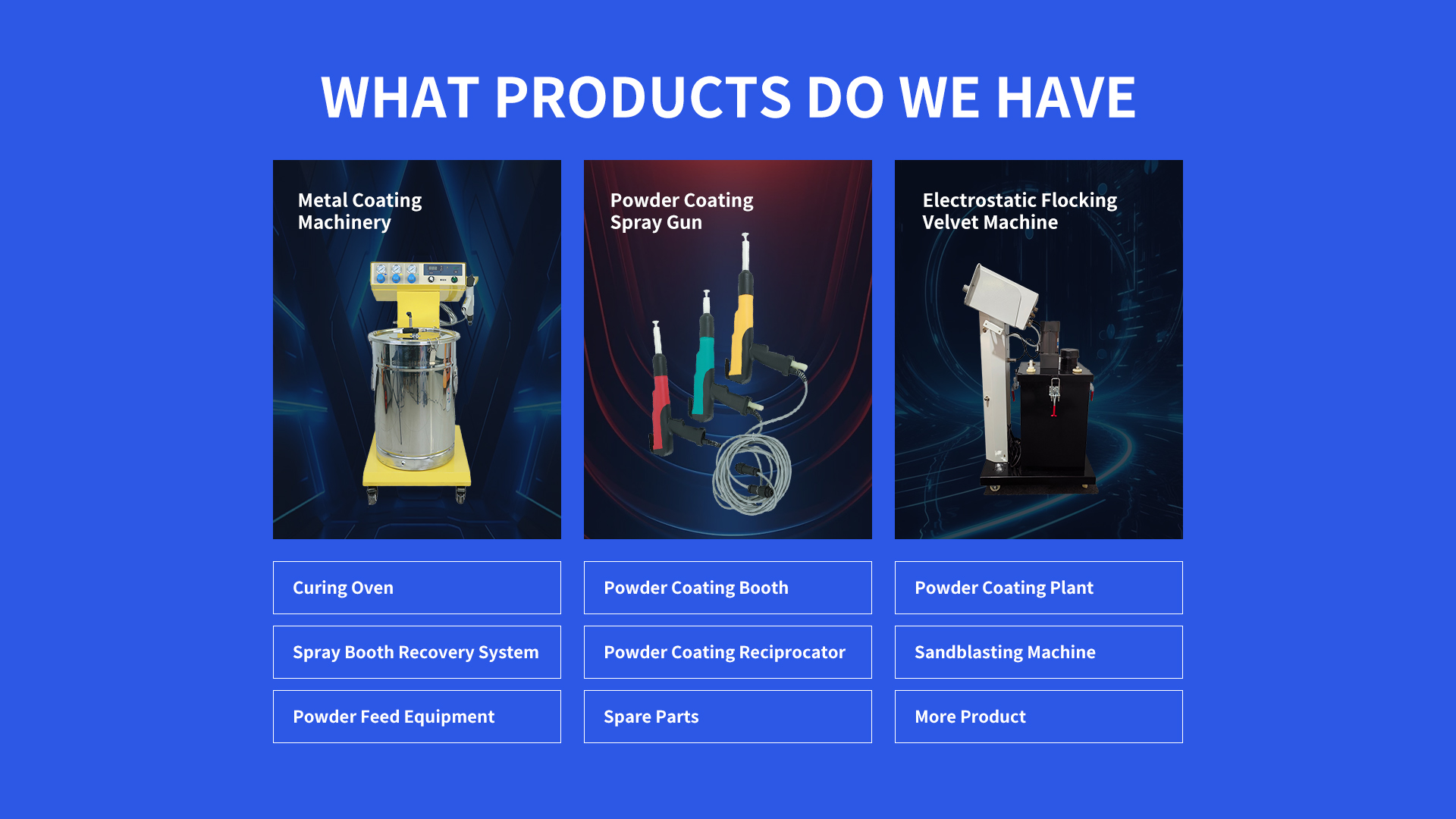

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com